Représentant moulin de saelen sud de la france

-

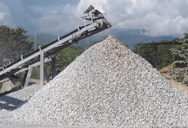

fabricant de concassage vente de concassage de calcaire

-

convoyeurs pour concasseurs dinde

-

mineurs d'or des outils et de l'equipement

-

crusher zone in baramati pune

-

Petit Mobile Concasseur à Mâchoires

-

types broches de rectification

Resistance to Grinding and Cement Paste Performance of Blends

2021年4月19日 Herein, we evaluate experimentally the interactions among clinker, limestone and gypsum during the final grinding stage in Portland cement production. We present a

Bavarder sur Internet

Effects of alternative calcium sulphate-bearing materials on

2021年6月1日 Clinker was grinded and blended with different percentages of gypsum, anhydrite, mixture of both and limestone as an additive in a vertical industrial roller mill at Beni

Bavarder sur Internet

Review of the Effect of Grinding Aids and Admixtures on the

2023年11月6日 The fineness of cement defines the grinding extent of the cement clinker alongside gypsum and other materials in the milling machine . Cement properties are highly

Bavarder sur Internet

Improvements in New Existing Cement Grinding

Improvements in New Existing Cement Grinding Mills by Tim Nowack . ... the heat generated can increase mill temperature to > 120⁰ C causes excessive gypsum dehydration media coating if mill ventilation is poor. Types of

Bavarder sur Internet

Role of Gypsum in Cement and its Effects –

The mixture then sent to final grinding process. For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 2.5%. ... Effects of Gypsum on Cement. Gypsum prevents Flash

Bavarder sur Internet

Cement grinding Vertical roller mills VS ball mills

In order to ensure an adequate dehydration of the gypsum also when grinding cement in a vertical roller mill, the lay-out, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a

Bavarder sur Internet

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, ... Heat generated in the grinding process causes gypsum (CaSO 4.2H 2 O) to lose water, forming bassanite (CaSO 4.0.2-0.7H 2 O) or γ-anhydrite (CaSO 4.~0.05H 2 O).

Bavarder sur Internet

use of gypsum in cement grinding mill - Grinding Mill China

2013年4月10日 Hot Products Used for use of gypsum in cement grinding mill hpc cone crusher pfw impact crusher cs cone crusher mtw milling machine mobile crusher vsi crusher. Cement mill Manufacturers – Grinding Mill Suppliers,Grinding Mill ...

Bavarder sur Internet

Slag Mill, Slag Grinding Mill - Cement Plant

Vertical mills are generally used for grinding slag powder. A vertical cement mill is also called a vertical slag mill. It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding. The vertical cement mill of AGICO CEMENT is inseparable from the following points:

Bavarder sur Internet

scope of gypsum in cement industry – Grinding Mill China

National Gypsum Company. A fully-integrated manufacturer and supplier of products and services used worldwide in building and construction, with primary emphasis on gold bond brand gypsum » More detailed MBA PROJECT IN CEMENT INDUSTRY – Docstoc – We Make . Jun 21, 2010 CHAPTER- I INTRODUCTION VALUATION OF EQUITY SHARES: Every

Bavarder sur Internet

why gypsum is used in cement grinding – Grinding Mill China

Use of FGD Gypsum in Cement Production Keywords: FGD,Gypsum,cement,Mcfalls Created » Free online chat! Ball mill used in cement industry for grinding gypsum, cement Ball mill is the cement grinding mill. Cement mill manufacturer Gulin supplies ball cement mill for sale. Cement ball grinding mill supplier in China, USA. » Free online chat!

Bavarder sur Internet

Cement Mills Optimization--- The Quality Perspective - LinkedIn

2019年6月13日 Overview: Cement Milling / Finish grinding is the last unit operation in the cement manufacturing process (Excluding Cement Packing). However, is most critical not only with regard to power ...

Bavarder sur Internet

What Is Gypsum ? - Gypsum Grinding Mill,Gypsum Grinding

2022年9月29日 Gypsum is a monoclinic crystal system mineral, and its main chemical component is calcium sulfate (CaSO4) hydrate. Gypsum is a widely used industrial and construction material. Can be used for cement retarder, gypsum building products, model making, medical food additives, sulfuric acid production, paper filler, paint filler, etc.

Bavarder sur Internet

Facilitating cement grinding in vertical mills - Cement

Summary: In the cement industry, the necessity of continuous improvements in the grinding process and the related cost reduction has promoted the proliferation of vertical cement mills worldwide. These particular mills

Bavarder sur Internet

Product Knowledge-Grinding Mill,Gypsum Grinding Mill,Raymond Mill ...

2016年6月24日 Clirik is the largest grinding mill manunfacturer of china,the grinding mills products included gypsum grinding mill,calcium carbonate grinding mill etc,kinds of stone grinding mill.clirik has become ... is calcium sulfate (CaSO4). Gypsum is widely used as industrial materials and building materials. It can be used as cement retard

Bavarder sur Internet

Small Capacity Ball Mill Capacity 100kg Ceramic

capacity 100kg ceramic grinding gypsum cement clinker ball mill mill with discharge cover Ball mill introduction Ceramic ball mill mainly used to mix and grind the material, the final product has average fineness. It is suitable for

Bavarder sur Internet

cement grinding Unit

Equipment in cement grinding plant. The cement grinding machine includes cement vertical mill, cement ball mill, cement roller press, cement seperator, conveyor and other cement equipment.We can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure smooth production with less investment and high profit.

Bavarder sur Internet

Effects of Mill Speed and Air Classifier Speed on Performance of

2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

Bavarder sur Internet

Process Training Ball Mill - INFINITY FOR CEMENT EQUIPMENT

Just 4 % of the energy is used for comminution. Nevertheless when grinding is required the ball mill is the most accepted element in the cement grinding. The reasons are high reliability, the good possibility of gypsum dehydration, “simple” operation (does not necessarily mean efficient) and the easy to maintain construction.

Bavarder sur Internet

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, ... Heat generated in the grinding process causes gypsum (CaSO 4.2H 2 O) to lose water, forming bassanite (CaSO 4.0.2-0.7H 2 O) or γ-anhydrite (CaSO 4.~0.05H 2 O).

Bavarder sur Internet

Raw mill - Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into

Bavarder sur Internet

Cement grinding Vertical roller mills VS ball mills

In order to ensure an adequate dehydration of the gypsum also when grinding cement in a vertical roller mill, the lay-out, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper temperature in the mill circuit.

Bavarder sur Internet

Articles liés

- diagramme schématique de l'industrie du broyeur

- fournisseurs de mines de charbon de l usine de broyage

- minerais de fer philippine

- machines pour broyer le soufre

- utilise le charbon machoire prix de concasseur afrique du sud

- utilisé moulin 3 rouleau

- machine de rainurage de rouleau de moulin de sbr

- Concasseur à cone principal agrégat de vente

- clinker marteaux concasseur a rouleaux vs

- concasseur à machoire de manganese

- Usine de traitement de minerai pper à vendre aux EtatsUnis

- dont ils sont les broyeurs à marteaux results

- Consommation d'énergie pour le broyage

- brazil iron sand crushing plant

- concasseur apa yang dimaksud dengan

- vitesse du reducteur convoyeur a bande

- devonsnous extraire de la pyrite

- les mines de charbon en pakistan

- highly recommended mini mobile jaw crusher

- fungsi broyeur à cylindres

- concassage des matières premières

- ep sur convoyeur bande

- calcaire type d'équipement de concassage

- cot de l'écrasement et exécuter à Charlotte

- l exploitation minière et des équipements de génie civil

- petit broyeur de roche à vendre En Allemagne

- diagramme et du circuit de commande pour concasseur

- équipement de sable pour l039arret de chemin de fer

- prix du broyeur du yunnan

- concasseur de charbon liste de clients