broyeurs à rouleaux verticaux de ciment contre broyeurs à boulets

-

poudre de dolomite prix dusine

-

Projection de films à l avance

-

trous de la grille conidur pour broyeur a marteaux

-

broyeur de charbon mobile à louer

-

concasseurs mobiles doccasion en allemand

-

vertical concasseur indonésie

HIGH SHEAR MILLS - DenimoTech A/S

Colloid Mill features. Delivered fully assembled as complete units; Milling zone with pattern of grooves and teeth for efficient droplet dispersion; Continuously variable speed optimizes the

Bavarder sur Internet

Design and development of high shear mixers ... - ScienceDirect

2021年3月15日 In this paper, a critical review has been carried out on high shear mixers based on applications and uses, and their design and development in recent years. For a better

Bavarder sur Internet

Hygienic Boston Shearmill High Intensity Wet Mill Inline - Admix

The Boston Shearmill ® (BSM) series of inline wet mills surpasses the capabilities of conventional shear pumps and colloid mills by providing very high throughputs at extreme

Bavarder sur Internet

High shear mixers: A review of typical applications and studies on ...

2012年7月1日 High shear mixers (HSMs), also known as high shear reactors (HSRs), rotor–stator mixers, and high shear homogenizers, are characteristic of high rotor tip speeds

Bavarder sur Internet

Homogenizer Mill for Modified Bitumen Massenza S.r.l.

Continually improved and optimised over the years to ensure the highest quality of PMB produced by our customers, the special rotor-stator configuration of our homogeniser mill leads to a very high shear action towards the polymer

Bavarder sur Internet

PMB – MODIFIED BITUMEN - Marini - FAYAT

The plant is specially designed for polymer modification of bitumen with a capacity up to 40ton/h (theoretical capacity, with 5% SBS granular polymer and bitumen temperature at 180°C) and is fitted into a containerized body for

Bavarder sur Internet

modiFALT – Tekfalt

modiFALT’s specially designed 160kW high shear mill is developed by the MARINI MAKİNA engineers for the best working performance with granule polymer types (e.g. SBS) and it ensures polymer modification with less than

Bavarder sur Internet

Detachment of the Polymer Melt from the Roll Surface:

2004年5月1日 During the shear roll milling process the polymer melt needs to continuously stick to one roll and periodically to stick and then to detach from the other roll (at the nip).

Bavarder sur Internet

Continuous Manufacturing of Cocrystals Using Solid State Shear

2017年12月12日 ABSTRACT: Solid state shear milling (S3M) is reported as a scalable, continuous, polymer-assisted cocrystallization technique. A specially designed milling pan

Bavarder sur Internet

Towards high-performance all-polyethylene materials by a two

2021年7月16日 In this study, we proposed a unique continuous two-step two-roll mill processing method to prepare high-performance self-reinforced polyethylene materials of high-density

Bavarder sur Internet

Continuous Shear Roll Milling of Gun Propellants

1). This pilot scale shear roll mill had two 75 mm rolls and they were powered by two separate electrical drives with motor ratings of 2 HP and which could rotate at different rotational speeds. This shear roll mill was used with simulants to understand the basic flow and heat transfer mechanisms of the process. In these experiments inert polymeric

Bavarder sur Internet

Design and development of high shear mixers ... - ScienceDirect

2021年3月15日 In general, constant tip speed and a shear gap is the primary parameter used for the scale-up of high shear mixers. Recently, James et al., 2017a , James et al., 2017b studied the process scale-up of Silverson batch HSMs from 1 L to 600 L directly based on the power constant, mixing, and emulsification.

Bavarder sur Internet

Intercalation and exfoliation of talc by solid‐state shear ...

2005年2月14日 The intercalation and exfoliation of talc have been realized by solid-state shear compounding (S 3 C) using pan-mill equipment that can exert fairly strong shear forces and has multifunctions such as pulverizing, mixing, and activation on materials. The structural features of pan-mill also show prospective in delaminating layered minerals.

Bavarder sur Internet

(a) General configuration of three roll mill, (b) High shear

Download scientific diagram (a) General configuration of three roll mill, (b) High shear mixing region between the three roll from publication: Enhancement of Electrical Conductivity and ...

Bavarder sur Internet

Detachment of the Polymer Melt from the Roll Surface:

2004年5月1日 The wall slip of the polymer phase itself is typically observed above a critical shear stress. Such slip at the wall of the polymeric binder gives rise to processing difficulties and challenges ...

Bavarder sur Internet

Pan mill type equipment designed for polymer stress reactions ...

A theoretical analysis of the structure and milling process of the novel equipment is given, which demonstrates that during pan milling the pan mill type equipment could exert reasonably strong pressure and shear forces on the materials owing to its particular structure. The materials were shown to move in a spiral manner.

Bavarder sur Internet

Detachment of the Polymer Melt from the Roll Surface:

2004年5月1日 The detachment behavior of a polymer melt from the hot roll surface/s during roll-driven processes affects the maximum production rates achievable in various processes including calendering, embossing and shear roll milling. Here the continuous shear roll milling process is used to investigate the conditions that lead to the detachment of the polymer melt from the

Bavarder sur Internet

Polymer Rubber Roll Mills Labtech Engineering Milatech USA

Lab Laboratory Polymer and Rubber two roll mills from table top up to 200mm. Electric heating or optional heated cooled from internal oil circulating unit. ... Heavy duty floor standing two roll mill sizes from 110 to 200 mm. Equipped with True Heat, 3 zone roll heating for

Bavarder sur Internet

Intercalation and exfoliation of talc by solid-state shear

The intercalation and exfoliation of talc have been realized by solid-state shear compounding (S3C) using pan-mill equipment that can exert fairly strong shear forces and has multifunctions such as pulverizing, mixing, and activation on materials. The structural features of pan-mill also show prospective in delaminating layered minerals.

Bavarder sur Internet

A computer-controlled four-roll mill for investigations of particle

2006年4月21日 Flow birefringence studies of a concentrated polystyrene solution in a two‐roll mill. I. Steady flow and start‐up of steady flow. Journal of Polymer Science Part B: Polymer Physics, Vol. 30, Issue. 12, p. 1329.

Bavarder sur Internet

Shear thinning - Wikipedia

Shear thinning in a polymeric system: dependence of apparent viscosity on shear rate. η 0 is the zero shear rate viscosity and η ∞ is the infinite shear viscosity plateau.. At both sufficiently high and very low shear rates, viscosity

Bavarder sur Internet

Polymer International

2004年12月6日 In this paper, polypropylene (PP)/organophilic montmorillonite (OMMT) nanocomposites were successfully prepared without any compatibilizers by solid-state shear compounding (S3C) using pan-mill equip...

Bavarder sur Internet

Design and development of high shear mixers ... - ScienceDirect

2021年3月15日 In general, constant tip speed and a shear gap is the primary parameter used for the scale-up of high shear mixers. Recently, James et al., 2017a , James et al., 2017b studied the process scale-up of Silverson batch HSMs from 1 L to 600 L directly based on the power constant, mixing, and emulsification.

Bavarder sur Internet

Shears/Shearing Machines for Steel Rolling Mill - The Steefo Group

Shearing machines are multipurpose devices used in the cutting of steel. A Shearing machine is an integral part of a hot rolling mill, installed for cutting front/tail end, cobbling, length cutting for cooling bed and commercial length cutting for TMT Bar.

Bavarder sur Internet

Numerical simulations of the flow of dilute polymer solutions in a

1997年10月1日 Io*r~d l~id ELSEVIER J. Non-Newtonian Fluid Mech., 72 (1997) 187-218 Numerical simulations of the flow of dilute polymer solutions in a four-roll mill J. Feng, L.G. Leal Department of Chemical Engineering, University of California, Santa Barbara, CA 93106, USA Received 12 November 1996; accepted 27 March 1997 Abstract We study the startup flow of

Bavarder sur Internet

To Mix or Mill: Thick Film Paste and Ink - Polymer Innovation Blog

2019年2月18日 The viscosity of the paste is typically within the following ranges when measured at room temperature on Brookfield viscometers at low, moderate and high shear rates. Figure 1. Schematic drawing of three-roll mill: (1) feed roll, (2) center roll, (3) discharge roll, (4) discharge blade, (5) first nip, (6) second nip, and (7) apron

Bavarder sur Internet

Effects of Shear Modulus of Polymer Gels SpringerLink

Where Y and X are the shear stress and the shear deformation. The bulk (K) and shear (µ) moduli are related with the second derivatives of F with respect to V and X, respectively [1].The shear modulus given by Flory’s theory is µ = v e RT, with v e the effective number of chains per unit volume at 6 temperature [2]. In most of the experiments, the gel is free of macroscopic

Bavarder sur Internet

Continuous Rotating Shear MK Engineering Solutions

MK Engineering Solutions - Manufacturer Exporter of Rolling Mill Parts, all types of Rolling Mill Stand, Gear Gearboxes, Shearing Machines, Furnace Pusher Furnace Ejector, ... Main shear body with cover provided for safety of men machinery Download Brochure. Reach Us. E-91, Focal Point, Mandi Gobindgarh - 147301,

Bavarder sur Internet

A computer-controlled four-roll mill for investigations of particle

2006年4月21日 Flow birefringence studies of a concentrated polystyrene solution in a two‐roll mill. I. Steady flow and start‐up of steady flow. Journal of Polymer Science Part B: Polymer Physics, Vol. 30, Issue. 12, p. 1329.

Bavarder sur Internet

Fabrication of PVDF/graphene composites with enhanced β phase

assisted by Solid State Shear Milling (S3M) technology, was provided to prepare PVDF/GP composite with GP uniformly dispersed in PVDF matrix and the improvedb phase at large State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute of Sichuan University, Chengdu 610065, China. E-mail: [email protected]; Fax: +86-

Bavarder sur Internet

Articles liés

- broyeurs à marteaux à vendre à lusaka Microsoft

- broyer le minerai dans les mines

- calcaire raymond moulin circuit ouvert broyage

- minerai de cuivre et d r

- concasseur à mâchoires indianapolis menu

- certification de la gestion des concasseurs

- concasseurs a circuit ferme et ouvert

- introduction a la plaque de la machine de broyage

- travaux sur les transports

- capcitor pour Congo de concassage de pierre

- concasseur à mâchoires TPH vendre

- lime rock concasseur de pierre

- approvisionnement de broyeur de pierre ponce

- Feldspar Ball Mill Grindingmoulin

- pierre concasseur pathanamthitta district

- chambre sud africaine des mines

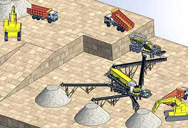

- mise en page gravier installation de concassage

- baccellieri bros crusher vendre

- broyeur à percussion vertical de larbre pour le clinker en Cameroun

- billes de broyage produsen tiges

- indien la machine de broyage de ciment

- prix des petits concasseurs mobiles

- fournisseur de pièces de rechange pour usine de concassage en inde

- SBM mobile de concassage materiel de dragage de l'or

- concasseur tempurung concasseur

- maquinaria minera en chili

- broyeur de pierres fines machine

- entreprise de transport a

- meuleuse en bton diamant malaisie

- pulvérisateurs de meunerie