faux roche concasseur

-

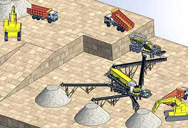

vente broyeur de pierres fabrication de sable carrière de pierre

-

hydrauliques de démolition primaire concasseur chinois

-

fl grand broyeur à ciment vertical

-

machines encombrement Moulin

-

High Efficiency Ball Mill

-

moteur diesel portable broyeur de pierres visakhapatnam

Predictive Controller Design for a Cement Ball Mill

This paper addresses the design of predictive controller for the cement grinding process using the state-space model and the implementation of this

Bavarder sur Internet

BALL MILLS Ball mill optimisation - Holzinger Consulting

As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2

Bavarder sur Internet

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the

Bavarder sur Internet

Thomas Holzinger, Holzinger Consulting, grinding system

Due to growing global cement markets in the years before 2008, many plants upgraded their existing ball mill systems with pre‑grinders (HPGR, roller presses, or VRM pre‑grinders) to

Bavarder sur Internet

Optimization of Cement Grinding Operation in Ball

Optimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding of ...

2004年12月10日 The absolute fineness of the ball diameter and the ball charge grading are important factors for the optimal operation of a ball mill. Therefore, the effects on breakage

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding of ...

2004年12月1日 An industrial scale FLSmidth® three-compartment cement grinding ball mill operating in open circuit was sampled at the steady state conditions.

Bavarder sur Internet

Effect of Grinding Aids in Cement Grinding - IOPscience

2018年8月1日 In fine grinding of cement in a ball mill, it is sometimes impractical to grind finer in a dry state. Even though the chemical reactivity requires the material to be dry ground, it is

Bavarder sur Internet

Analysis of the efficiency of the process in closed circuit ball mills

Ball mills for fine grinding cement clinker and additives are widely used around the world. To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air

Bavarder sur Internet

Ball Mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding of ...

2004年12月10日 During the last decade, semi-finish-grinding plants have been used more and more for the energy efficient grinding of high-quality cement. In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energy demand for grinding significantly.

Bavarder sur Internet

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills

Bavarder sur Internet

Ball mill - FLSmidth Cement

%PDF-1.6 %âãÏÓ 91 0 obj > endobj 109 0 obj >/Filter/FlateDecode/ID[9B8DEA45C96DEC49BD22C1F22EB4DA3F>]/Index[91 32]/Info 90 0 R/Length 101/Prev 1205833/Root 92 0 R ...

Bavarder sur Internet

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 Despite various research conducted on ball mills, ... of cement clinkers was higher with cylpebs grinding media than with steel balls in a ball mill. Table 2. Adapted from [51].

Bavarder sur Internet

Vertical roller mill vs. ball mill for cement grinding: Comparison

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant. VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainability.

Bavarder sur Internet

`Grinding Aid Effectiveness in Cement Ball Mill - Academia

Grinding Aid Effectiveness in Cement Ball Mill Web: bulawali Email: bulawali@gmail, ali@bulawali LinkedIn: Ali Bulawali Date: Sep -2016 The introduction of the grinding aid (GA) has been started more than 50 year ago, to facilitate clinker grinding in cement mills improve mill output despite of the above features, the wear of mill interior parts

Bavarder sur Internet

Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

The installation of liners. Length Diameter Ratio. The length-diameter ratio of the cement ball mill is relatively large. For mills of open-circuit grinding system, the length-diameter ratio is usually between 3.5 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closed-circuit grind system, in order to increase the material flow rate, the length ...

Bavarder sur Internet

Grinding Ball Ball Mill Balls For Sale Ball Mill Media - Cement

Ball mill balls supplier – AGICO CEMENT. Ball mill ball is a hot-sale product of our company, we also supply other ball mill parts including ball mill girth gear, ball mill pinion, ball mill trunnion, and ball mill bearing house according to the requirements of clients. If you have any questions, welcome to ask!

Bavarder sur Internet

Cement Ball Mill Maintenance

BALL MILL INSPECTION PROCEDURE. source : thecementgrindingoffice Introduction. This document is intended to help the staff of the cement plants. On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement product.

Bavarder sur Internet

Matrix model of the grinding process of cement clinker in the ball

2017年11月24日 Matrix model of the grinding process of cement clinker in the ball mill. Rashid R Sharapov 1. Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 307, International Conference on Mechanical Engineering and Applied Composite Materials 23–24 November 2017, Hong Kong Citation Rashid R Sharapov

Bavarder sur Internet

Ball mill - FLSmidth Cement

%PDF-1.6 %âãÏÓ 91 0 obj > endobj 109 0 obj >/Filter/FlateDecode/ID[9B8DEA45C96DEC49BD22C1F22EB4DA3F>]/Index[91 32]/Info 90 0 R/Length 101/Prev 1205833/Root 92 0 R ...

Bavarder sur Internet

(PDF) A study of different grinding aids for low-energy

2023年10月23日 the material inside the cement ball mill and their impact on the . overall grinding circuit were studied b y Top rak, Altun, and Benzer (2018), T oprak and Benzer (2019), and T oprak et al., (2020 ...

Bavarder sur Internet

Grinding Ball Ball Mill Balls For Sale Ball Mill Media - Cement

Ball mill balls supplier – AGICO CEMENT. Ball mill ball is a hot-sale product of our company, we also supply other ball mill parts including ball mill girth gear, ball mill pinion, ball mill trunnion, and ball mill bearing house according to the requirements of clients. If you have any questions, welcome to ask!

Bavarder sur Internet

`Grinding Aid Effectiveness in Cement Ball Mill - Academia

Grinding Aid Effectiveness in Cement Ball Mill Web: bulawali Email: bulawali@gmail, ali@bulawali LinkedIn: Ali Bulawali Date: Sep -2016 The introduction of the grinding aid (GA) has been started more than 50 year ago, to facilitate clinker grinding in cement mills improve mill output despite of the above features, the wear of mill interior parts

Bavarder sur Internet

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al. 2013).

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding of ...

2004年12月10日 During the last decade, semi-finish-grinding plants have been used more and more for the energy efficient grinding of high-quality cement. In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energy demand for grinding significantly.

Bavarder sur Internet

Cement Grinding - Cement Plant Optimization

Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe ... while the coarse fraction falls and is discharged from the bottom and send back to mill for regrinding.

Bavarder sur Internet

Application of Vertical Roller Mill in Cement Production

Secondly, VRMs have a lower noise level, making them more suitable for use in urban areas. Finally, VRMs produce a more uniform and consistent product, reducing the need for regrinding. One of the primary benefits of using VRMs in cement production is their ability to produce cement with a lower specific energy consumption (SEC).

Bavarder sur Internet

中国定制高品质大阳水泥球磨机研磨球制造商供应商 ...

生产工艺流程. 原料选择:精心挑选优质合金钢,确保卓越的性能和耐用性。; 成型:使用先进的铸造或锻造技术将选定的原材料熔化并形成所需的形状。; 热处理:成型的磨球经过精密的热处理工艺,包括淬火和回火,以达到最佳的硬度和韧性。; 表面处理:采用喷丸或钝化等特殊表面处

Bavarder sur Internet

Articles liés

- usine de concassage de phosphorite

- pe pex seri concasseur à machoires

- utilisé charbon capacité de broyage de l usine tph

- portable broyeur de pierres réduction du bruit db

- broyeurs à cône hp 400 à vendre de

- broyeur de pierres ex surabaya

- usine de concasseur de pierre prix inde gujarat

- petite machine à laver à petite échelle de minerai d or

- rapport de reduction dans le broyeur a billes conique

- prix concasseur de sable

- concasseur de pierres d occasion et concasseur mobile sur chenilles vente usa

- results crasher le minerai de fer de gypse

- plantes concasseurs de rechange

- Venezuela 470 tph Concasseur de pierres

- concasseur de pierres de granit d afrique du sud

- Fabricant de grenaillage delhi

- Les prix du matériel de concasseur en France

- shell britador de mandbula e martelo

- britador de pedra móvel pará venda e aluguel

- broyeur horizontal à cônes

- or trommel plantes a vendre triturateur afrique du sud

- Le moulin Zimbabwe

- plaque de criblage pour broyeur de pierres

- Machine de broyage de verre utilisée

- convertir la roche de mine concassée en verges

- petite plante du concasseur portable

- grande usine de concassage mobile pour le processus vente

- proses de broyage et de calibrage

- coal broyeur used in coke oven plant

- cendres volantes de concassage broyeur raymond