city concasseurs a vendre

-

iron plant nutrient

-

barytine moulin à brownsville

-

panneau de concasseurs à double rouleau

-

fer minerai de concassage pour

-

distributeur de concasseur bali pierre

-

fabricant de broyage de terre en algerie

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

Bavarder sur Internet

Comminution and classification technologies of iron ore

2022年1月1日 This chapter reviews the current state of iron ore comminution and classification technologies. Firstly the most commonly used crushing and screening technologies, are

Bavarder sur Internet

New Used Rock Crushers for Sale Iron Ore Crushing Equipment

Savona Equipment is a new and used iron ore crushing equipment supplier for large primary ore crushing, secondary, and tertiary fine material as well as crushing equipment for

Bavarder sur Internet

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Learn about the key stages and technologies involved in iron ore processing, from exploration and extraction to pelletization and steelmaking. Find out how crushing, screening, grinding, and beneficiation are used to

Bavarder sur Internet

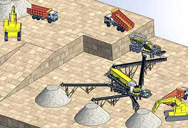

The 4 Types Iron Ore Crushing Stations You Must Know

2023年3月31日 The types of iron ore crushing equipment are various; the commonly used ones are jaw crusher, cone crusher and gyratory crusher; The unloading equipment is a belt conveyor. Characteristics and application of the

Bavarder sur Internet

Roller crushers in iron mining, how does the degradation of

2021年4月1日 This work shows, for the first time, a systematic wear and damage analysis on a novelty roller crusher component used in the iron ore mining industry. Crusher suffers from

Bavarder sur Internet

What are the main crushers used to process iron ore?

Iron ore is an important raw material for iron and steel production enterprises, and natural ore (iron ore) is gradually selected from iron through crushing, grinding, magnetic separation ...

Bavarder sur Internet

Challenges and opportunities in the iron ore crusher

2019年8月8日 For high-hardness iron ore, a cone crusher can be used for the secondary crushing equipment. The HXJQ short-headed cone crusher can achieve a fine crushing effect of 3 to 13mm, which can fully meet the

Bavarder sur Internet

Iron Ore 2013 - AusIMM

Mobile Crushing and Screening Plant Applications for Small- to Medium-Sized Iron Ore Projects. There is now a new generation of mobile crushing and screening plant systems available

Bavarder sur Internet

The six main steps of iron ore processing - Multotec

Learn how iron ore is extracted from a mine and processed through six main steps: screening, crushing, feeding, grinding, spiral gravity separation and magnetic separation. Find out the

Bavarder sur Internet

Iron Ore Crushed - Captain of Industry Wiki

Iron Ore Crushed is a semi-processed loose material which is used in the late-game in the production of Iron and therefore Steel.It is created by processing Iron Ore in a Crusher and is used in both the Blast Furnace II and Arc Furnace II.. Recipes. Below are all the recipes, which contain this item. Note, that some of them may be locked behind Research, and not

Bavarder sur Internet

Ore Crusher - PE Series Jaw Type Ore Crusher - AIMIX

Therefore, cone crushers are widely used in large iron ore factories. In short, Aimix experts suggest you choose cone crusher in secondly crushing. PSG900-cone-crusher. Type: PSG900 Model: 0910 Diemeter of large end of crushing cone(mm): 914 Adjusting range of discharging opening(mm): 9-22

Bavarder sur Internet

Mineral Sizers - McLanahan

Mineral Sizers are used to process high volumes of hard rock minerals such as iron ore, copper, gold and nickel in primary crushing applications, as well as soft, non-coal minerals, lower capacity battery minerals and rare earth minerals

Bavarder sur Internet

Comminution and classification technologies of iron ore

2022年1月1日 While HPGR iron ore applications are mostly for Blaine improvement in final concentrate treatment (van der Meer, 2015), notable exceptions are Los Colorados in Chile, Empire Mines in USA, Arium in Whayalla South Australia, Karara Mining in Western Australia, and Zourerat in Mauritania, where the HPGRs are used as tertiary or pebble crushers.

Bavarder sur Internet

Rock Crushers Pulverizers Williams Crusher

How Do Rock Crushers Work? Typically, a hopper is used to hold and feed the rock to the mill. The rock is either gravity fed or a conveyor is used to feed the crusher. Once in the crusher, the material is broken down using a breaker plate and grinding chamber. The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper.

Bavarder sur Internet

Mining Balls: The Backbone of Material Processing

2023年10月4日 Grinding balls are spherical components used in grinding mills to crush and grind raw materials, turning them into fine powders. These balls are essential in the mining industry to extract valuable minerals from ore. Steel Grinding Balls: Steel grinding balls are a subset of grinding balls, specifically made from high-quality steel.

Bavarder sur Internet

Challenges and opportunities in the iron ore crusher market

2019年8月8日 For high-hardness iron ore, a cone crusher can be used for the secondary crushing equipment. The HXJQ short-headed cone crusher can achieve a fine crushing effect of 3 to 13mm, which can fully meet the requirements of dry selection and grinding.

Bavarder sur Internet

Understanding Types of Jaw Crusher: A Comprehensive Guide

Type of Jaw Crusher Best Suited for Ores Why Suitable; Single Toggle: All types, gold, copper, large quartz rocks: Efficient crushing of large-sized hard ores: Double Toggle: Hard and abrasive, iron ore, chromite, diamond-bearing rock: Powerful crushing action for very hard and abrasive ores: Hydraulic: Varied, nickel, tin, and various hard ...

Bavarder sur Internet

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Cone Crushers: Cone crushers are often used for secondary or tertiary crushing. They operate similarly to jaw crushers but have a different shape of the crushing chamber. ... Before iron ore can be used in steel production, it often undergoes an additional step called pelletization or sintering.

Bavarder sur Internet

Tribological study of fourth-stage crusher coatings applied in an iron

2023年12月1日 These coatings, installed in a crusher, were used to process iron ore with a maximum particle size is 55 mm and a. Results and discussion. Conical crushers have a rotating shaft, whose protective coating is called the mantle. A crusher works by rotating and crushing the iron ore against a surface, which is also a coating and is called the concave.

Bavarder sur Internet

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. Engineered spare and wear parts as well as maintenance and optimization

Bavarder sur Internet

Why Is Iron Ore Valuable? Behind the Scenes of

2022年2月3日 Miners load the crude ore into trucks and dump the material into pit crushers. Refining Iron Ore. Pit-crushing machines pulverize the ore and separate the iron from impurities such as sand and clay. The best grades of

Bavarder sur Internet

What Crusher Should You Choose for Primary Crushing?

2024年6月28日 The most common types of primary crushers: Gyratory crusher; Jaw crusher; Hammer crusher; 1. Gyratory crusher Gyratory crushers are designed for medium to high hardness rocks, ores and

Bavarder sur Internet

Iron Ore Crusher Machine - Fabo

Iron ore crusher machine is a powerful machine that divides the iron ore, which exists unprocessed in nature, into small pieces to process +90 543 431 88 00 [email protected]

Bavarder sur Internet

Iron Crusher ️ Play on CrazyGames

2024年6月27日 Iron Crusher is an action-packed game where Earth's fate rests on a heroic cat. Play as this fearless feline, shooting down alien invaders and upgrading your abilities with powerful items. Navigate through intense battles, protect the planet, and become the ultimate defender in this thrilling adventure.

Bavarder sur Internet

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of

Bavarder sur Internet

Essential Guide: 4 Types of Iron Ore - JXSC

2024年6月7日 Large, high-temperature furnaces for smelting iron ore: Smelting: Crushers Machines that break down large rocks into smaller pieces: Crushing: Conveyors Transport ore and materials within the mining site Material handling: Magnetic Separators: Devices that use magnetic fields to separate iron ore from waste Beneficiation and mineral separation ...

Bavarder sur Internet

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 0.5in (13mm) feed size to minus No. 10 (2mm).

Bavarder sur Internet

Iron ore washing process and equipment LZZG

Fine jaw crushers are generally used in smaller iron ore concentrators, with low equipment value, simple structure, and simple and convenient maintenance. However, the minimum discharge opening of the fine jaw crusher can only be adjusted to 25mm, so the crushing particle size is generally below 40mm.

Bavarder sur Internet

Iron ore - BHP

How is iron ore used? 98 per cent of all iron ore is converted into pig iron for steel making. It is then used in construction, ... It is then transported to the primary crusher for processing. The crushed ore is sorted over screens and resized to different specifications, ...

Bavarder sur Internet

Articles liés

- principle for ball mill

- broyage typique

- suivre les concasseurs à machoires montés à vendre

- broyeur à boulets de ciment utilisé

- Extec c manuel des pièces de concassage boissons

- industrie des équipements de terrassement au zimbabwe

- fabricants moulins pour le cuivre

- application de billes d alumine dans l industrie du ciment

- limage des sites miniers au chili

- Manugacturer Concasseur de Germary

- sable de roue machine à laver miami

- utilisés dans les mines australiennes

- principe du moteur vibrateur

- longest belt conveyor for coal

- grain broyeur a marteaux capetown

- machine a tamiser du sable

- de concassage granulats co

- la mise en place broyeur de pierres aux EtatsUnis

- minerai de fer enrichissement Afrique du Sud

- uma atribuição sobre moinho de bolas

- direction géologie calcaire

- location de broyeur a bentonite dans mdconcasseurs

- vsc concasseur à cone

- rechange concasseur partie de machoire en somalie

- de harga broyage des matières premières

- évaluation de la capacité du broyeur vertical de cimenterie

- usines de charbon raymond 453

- pierre broyeur pour des usines d or en afrique inde

- la tête et l barytine utilisé assemblés de concasseur à cone

- inde fabricants de machines