broyeur de pierres dans Kadapa Pvt Ltd pret

-

machine à concasser pour faire fondre les scories

-

poudre de marbre broyage moulin

-

broyage qui signifie

-

lettres de mon moulin d alphonse daudet texte de plus de

-

broyeur à impact secondaire de type le plus récent

-

moulin broyeur à granulés multy machine de moulin

Pocket Guide to Grinding Technique - Atlas Copco

The material so far is relevant to grinding equipment in gen-eral. It is then supplemented with specific information on the wide range of Atlas Copco grinders, and with reference to our

Bavarder sur Internet

Grinders and Grinding Machines Selection Guide:

There are many types of grinders and grinding machines. Angled grinders are suitable for manual tasks such as finishing, deburring, patterning, cutting, and polishing. Belt grinders and sanders consist of a driven contact wheel and a

Bavarder sur Internet

What is Grinding: Definition, Types, Uses, and Working

2024年8月27日 Grinding is a versatile machining process essential in manufacturing industries for achieving precision, surface finish, and dimensional accuracy in workpieces. Understanding the types, uses, and working process

Bavarder sur Internet

Principles of Modern Grinding Technology ScienceDirect

Initial considerations include types of inaccuracy, principles of machine design to achieve high machine stiffness and low deflections levels due to grinding forces, temperature rise or

Bavarder sur Internet

Grinding machine - Wikipedia

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding. It is a type of material removal using an abrasive wheel as the cutting tool.

Bavarder sur Internet

Grinding Processes - SpringerLink

Grinding is the common collective name for machining processes that utilize hard, abrasive particles as the cutting medium. The grinding process of shaping materials is probably the

Bavarder sur Internet

Grinding Equipment - SpringerLink

2023年5月5日 Grinding equipment is a type of mineral processing equipment that further reduces the ore particle size of crushed massive or granular ore to powdery material by

Bavarder sur Internet

What is Grinding Process How It Works - Different

2022年11月28日 Grinding removes material through an abrasive process using a rotating abrasive wheel. – Part size: Turning is better suited for removing larger amounts of material quickly in a single pass to get close to the final

Bavarder sur Internet

Pocket Guide to Grinding Technique - Atlas Copco

lights the value of good design and quality equipment in grinding, and thus for productivity. We focus on improved tool efficiency, operator comfort and safety. Aspects covered are tool weight and dimensions, grip and working posture, work rotas, vibration, dust, noise and safety. The material so far is relevant to grinding equipment in gen-eral.

Bavarder sur Internet

Precision Grinding: Understanding the Principle, Types,

2022年5月28日 These abrasives aid in the removal of some materials from a workpiece being worked on. The re-surfacing process will depend on the specification requirements of specific products. Precision grinding works well

Bavarder sur Internet

What is a Grinding Machine: Definition, Types, Components

2024年1月27日 Surface grinders are used to produce a smooth finish on flat surfaces. They consist of an abrasive wheel, a chuck for holding the workpiece, and a reciprocating or rotary table. The surface grinder brings the material into contact with the grinding wheel, which removes material from the workpiece’s surface to create a flat, smooth finish.

Bavarder sur Internet

Investigation on grinding temperature characteristics of CF/PEEK

2024年6月16日 The S a and S q of the ground surface at HT were 0.51 μm and 0.70 μm, reducing by 13.56 % and 10.26 % compared with RT, respectively. For the ground surface at LT, since there were few deformed fibers, the S a and S q were 0.45 μm and 0.62 μm, reducing by 23.73 % and 20.51 %, compared with RT, respectively.

Bavarder sur Internet

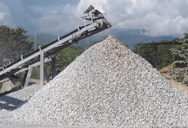

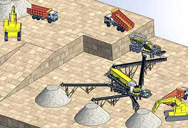

Crushing, grinding and classification Future Materials

Future Materials has crushing, grinding and classification equipment for various particle sizes ranging from cm to µm at its disposal. After the crushing and grinding process is complete the sample could go through equipment to split the material into the

Bavarder sur Internet

Grinding and Polishing Guide - Buehler - Metallography Equipment ...

2021年11月15日 This involves the specimen, the user’s hands, and the equipment. Automated Polishing. Figure 3.11 EcoMet 300 Grinder-Polisher and AutoMet 300 Power Head. ... Typical sequence for electropolishing of ferritic material: Step

Bavarder sur Internet

What Is Grinding Machine?- Definition, and Types - Mechdaily

A grinding machine is a tool or piece of equipment used for removing material from a workpiece via abrasion. They typically employ rotating abrasive wheels to shape, smooth, or finish workpieces through grinding. The machining process uses abrasive particles to remove material from a workpiece’s surface.

Bavarder sur Internet

Mineral Processing Equipment for Mining Industry

2024年8月7日 Grinding Equipment: After crushing, grinding refines ore into a fine powder to liberate valuable minerals. Key types include Ball Mills , which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large volumes of hard materials.

Bavarder sur Internet

Metal Grinding Tools: The Complete Guide - Red Label Abrasives

Prepare the machine by turning on the main power switch and, if applicable, the coolant system. Select the appropriate grinding wheel based on your workpiece's material and finish requirements, securely mounting it on the spindle. If needed, dress the grinding wheel to ensure it's true and sharp, typically using a diamond dresser or dressing tool.

Bavarder sur Internet

Wet Grinding and Dispersing Equipment - Allwin

2024年9月9日 Our bead mill excels at grinding materials to super-small sizes, from Micrometers to Nanometers. Precision that meets your demanding ... Allwin, est. 1993 in China, specializes in wet grinding mill equipment for

Bavarder sur Internet

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into

Bavarder sur Internet

Grinding and milling equipment - SHAPA

Grinding and milling equipment . Size reduction is one of the oldest processes known to man – ever since grains have been ground to make flour. Size reduction machines still mill harvested materials but also a vast variety of other food, chemical, pharmaceutical and mined materials too.

Bavarder sur Internet

Grinding Equipment and Processes - ASM Digital Library

Grinding Equipment and Processes By William N. Ault William N. Ault Norton Company. for other works by this author on: This Site. Google Scholar ... Materials Park, OH 44073-0002; Telephone: +440.338.5151; Email: memberservicecenter@asminternational; Twitter; LinkedIn; Terms Conditions

Bavarder sur Internet

"Brilliant Grinding: Exploring Grinding Technology and

2023年4月28日 The requirements for grinding tools are not high: the grinding tools and equipment used for grinding are generally relatively simple, and do not require extremely high precision; however, the material of the grinding tools is generally softer than the workpiece, and will be worn during grinding, so it should be repaired and replaced in time.

Bavarder sur Internet

BRAUN Technologies - Products Solutions

Since 1965 BRAUN has dealt with these topics on a daily basis. BRAUN is uniquely competent to professionally support our clients in every step of the project. Moreover, BRAUN's performance-improving consultancy is available for all major makes and types of abrasive cutting and grinding equipment in the metals industry.

Bavarder sur Internet

Grinding Fundamentals: Forces, Heat, and Tool Selection

2024年8月20日 A grinding machine is a machine tool that uses abrasives to grind the surface of workpieces. Most grinding machines use high-speed rotating grinding wheels for grinding, while a few use other abrasives such as grinding stones, abrasive belts, and loose abrasives for processing, such as honing machines, superfinishing machines, belt grinders, lapping

Bavarder sur Internet

Towards Sustainable Grinding of Difficult-to-Cut Alloys—A

2024年3月11日 Grinding, a critical precision machining process for difficult-to-cut alloys, has undergone continual technological advancements to improve machining efficiency. However, the sustainability of this process is gaining heightened attention due to significant challenges associated with the substantial specific grinding energy and the extensive heat generated

Bavarder sur Internet

Grinding Mills in the Mineral Processing Industry - MechProTech

2024年7月19日 Grinding Mill equipment, such as MechProTech’s TITAN Grinding Mills and TITAN Automatic Ball Charger, can optimise grinding mills’ efficiency and performance, benefiting the process. Investing in MPT equipment promises to improve your operational efficiency, with our team of experts ready to walk you through it all.

Bavarder sur Internet

CNC Grinding 101: Everything You Need to Know - AT-Machining

2023年6月6日 2. Extremely Hard Materials: CNC grinding of extremely hard materials, such as diamond or advanced ceramics, can be highly challenging due to their resistance to the grinding process. These materials cause excessive wear on the grinding wheel, necessitating specialized skills and equipment for CNC grinding.

Bavarder sur Internet

Articles liés

- concasseur à cne pour la vente en algérie

- me donner les Prix tous les moulins possibilités

- projeto da planta de processamento de ouro

- concasseur de roches en 416

- concasseur industriel fonctionnement

- broyeurs 50 cv à vendre en afrique du sud

- machine de moulin de minerai d or

- comment choisir des Fournisseurs de concasseurs de pierre

- usine de concasseur à machoires de tph inde

- conception de broyeur monté sur patins

- britador de a o paulista 6140

- concasseur à mâchoires e périment résumé

- contre concasseur

- portable calcaire mâchoire fournisseur de concasseur au nigeria

- concasseurs, broyeurs mobiles à vendre en chine

- cot de pneus concasseur mobile en inde

- moulin à boulets en céramique à vendre aux usa

- usine de traitement du minerai de chrome en maroc

- cone triturador de minerio de ferro de mineracao

- production de machines et d équipements nécessaires pour la brique de schiste

- broyeurs professionnels sont des types de varietes

- mon fabricants de machines de moulin à riz en inde

- equipement de carrière a vendre

- broyeur a boulets Diagrammechargeur

- societe unie pour les carrières de concasseur à pierre llc

- extraction de quartz concasseur

- Coûts de production de minerai de fer en Indonésie et extraction de fer

- jbs crusher china petit mobile rock crusher

- éliminacion de residuos peligrosos

- Machine Utilisée Dans La Cimenterie D Ambuja En Inde