recherche pierre pour ecraser les olives pour faire de huile

-

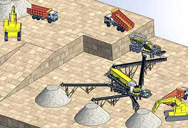

traitement du minerai broyeurs à marteaux wendt

-

conception et fonctionnement de la fraiseuse à boulets

-

les concasseurs pièces de rechange chine inde

-

entraînement lv pour broyeur à boulets

-

machine de fabrication de la rectification intérieure

-

centrale mobile pierre concasseur à vendre Philippines

Current Status of Copper-Ore Processing: A Review

2021年9月8日 For oxide copper ore and some sulfide ores, a combined flotation–hydrometallurgy technology is applied to produce copper concentrate and copper cathodes. The processing of this ore includes ore preparation, flotation, concentrate leaching,

Bavarder sur Internet

Copper Ore Processing Plants, Flow And Equipment

2024年10月25日 Copper ore Process. Copper ore is divided into sulfide ore, oxide ore and mixed ore according to its oxidation rate. The main technological process of copper ore is flotation. For refractory mixed copper ore and

Bavarder sur Internet

Processing of Complex Materials in the Copper

2020年7月6日 Pyrometallurgical processing of complex copper concentrates has been traditionally associated with the smelting of specific materials containing substantial concentrations of deleterious elements, such as arsenic

Bavarder sur Internet

Designs of new operating copper processing plants: process types ...

2021年1月8日 The article describes the largest operating processing plants for lowgrade copper sulphide ores of our time: 10 plants using the semi-autogenous grinding (SAG)

Bavarder sur Internet

Optimizing the Rougher Flotation Process of Copper Ore

2019年2月22日 This paper focuses on optimizing the parameters of the copper ore flotation process, which is the most expensive in obtaining copper concentrate, in order to improve

Bavarder sur Internet

Copper Processing: The Quest for Efficiency at Scale - E

Advances in copper processing technologies from the past 30 years nearly all fall into the category of “the bigger, the better” — higher volume flotation cells, massive high-pressure grinding rolls (HPGRs), super-sized concentrators. For

Bavarder sur Internet

Achieving step change performance in copper ore processing

Our proven solutions for copper ore processing include high availability sampling, elemental analysis, and particle size distribution data, providing accurate data in the timescale needed

Bavarder sur Internet

Increase in Production Capacity of Ultra-Fine Copper Powder for

2018年2月1日 Approx. 40% increase in production capacity of engineered powders plant at Hikoshima Smelting Co., Ltd. Mitsui Mining Smelting Co. Ltd. (President: Keiji Nishida;

Bavarder sur Internet

Optimizing the Metal Flow Process in a Copper Production Plant

Optimizing the Metal Flow Process in a Copper Production Plant by Employing a Technology Framework. Crimson Publishers. Wings to the Research. Case Report. ISSN: 2578-0255.

Bavarder sur Internet

Emission characteristics of heavy metals from a typical copper

2022年2月15日 The EF s from this studied plant were significantly lower than the recommended values in the emission factor manuals (National Bureau of Statistics, 2017), based on previous measurements of real copper smelting plants. This indicates that the studied copper plant had installed advanced APCDs with excellent performance on PM and HMs controls.

Bavarder sur Internet

Copper Mining and Processing: Processing Copper

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The

Bavarder sur Internet

Copper Processing Plant - JXSCTeam

The crushed material enters the second jaw crusher to get fine copper ore. After the crushing process, the copper ore is transported to the vibrating screen for screening, and the materials that meet the requirements are screened out and

Bavarder sur Internet

Copper Process Flowsheet Example - 911Metallurgist

2015年10月1日 A simplified schematic drawing of copper flotation flowsheet. Run-of-mine open pit ore will be crushed in a gyratory crusher. The crushed ore will be processed by means of semi-autogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate.

Bavarder sur Internet

Separation efficiency improvement of a low grade copper-gold

The copper concentrate grades achieved from the flotation circuit at Telfer have typically fallen well short of the theoretical achievable grades despite the majority of copper being hosted in high copper bearing minerals: chalcopyrite, chalcocite, bornite and others. The recovery of gold-containing pyrite to the

Bavarder sur Internet

Copper Beneficiation Process - JXSC Mineral

1. Copper Flotation. As a commonly used process for copper ore beneficiation, flotation can be used for the separation of copper sulfide and oxidized copper ores. The main process of copper ore flotation is rough as follows: ore crushing and screening → stage grinding stage flotation → concentration and dehydration → copper concentrate.

Bavarder sur Internet

First Commercialisation of the Albion ProcessTM Copper

to make an assessment of process flexibility and, critically, copper and cobalt recovery. Following this successful testwork, a decision was taken to convert the existing Sable copper/cobalt plant to an Albion ProcessTM plant capable of treating copper/cobalt concentrates containing refractory minerals such as chalcopyrite (CuFeS 2

Bavarder sur Internet

Copper Processing Plant - JXSC

Due to limited funding, a gravity separation process after the crushing stage is applied to recover copper sulfide ore, resulting in less minerals acquired. For improved recovery, we use our flotation machines to save on costs and ensure that enough ore is extracted after the grinding stage for copper sulphate manufacturing plants.

Bavarder sur Internet

The Recovery of Copper from Smelting Slag by Flotation Process

2017年2月8日 Taking into account that the slag contained more copper than ore, a series of flotation tests was conducted on copper smelting slag produced in an electric furnace of a copper plant in China. Based on the mineralogical analyses of slag, the tested copper smelting slag was composed of fine particles with complex association and dissemination, in which

Bavarder sur Internet

Gold CIP Processing Solution - JXSC Machinery

Crushing, grinding: The ore is first crushed and ground to extremely fine particle size to match the size of the subsequent gold extraction process. ... Diamond Wash Process; Copper Processing plant; Tin Ore Processing Plant; Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86-18879767229 [email protected]

Bavarder sur Internet

Copper Pressure Leaching Process - Metso

Get sustainable copper recovery from copper sulfides with Metso's copper pressure leaching process. ... Offers pressure leaching technology without fine-grinding; ... Improve performance with an accurate picture of the current

Bavarder sur Internet

First Commercialisation of the Albion ProcessTM Copper

to make an assessment of process flexibility and, critically, copper and cobalt recovery. Following this successful testwork, a decision was taken to convert the existing Sable copper/cobalt plant to an Albion ProcessTM plant capable of treating copper/cobalt concentrates containing refractory minerals such as chalcopyrite (CuFeS 2

Bavarder sur Internet

Extraction of Copper: Detailed Process - Science Info

2023年4月4日 The process of extraction of copper from its ores and preparing copper metal or chemical compounds for use in various goods is known as copper processing. ... The ore is ground into a fine powder and then

Bavarder sur Internet

A Review of the Flotation of Copper Minerals - ResearchGate

2017年7月4日 Copper is most commonly present in the earth’s crust as copper-iron-sulphide and copper sulphide minerals, for example, chalcopyrite (CuFeS2), bornite (Cu5FeS4) and chalcocite (Cu2S).

Bavarder sur Internet

Copper Powder - Green Line Corner

Ultrafine Copper Powder is used by MLCC, plating, magnetic mineral, rechargeable batteries, friction materials, diamond tools and major industries such as Energy, Military, MedIcal Transportation, Construction. What is the origin of the Ultra Fine Copper Powder? All our Ultra Fine powders are processed at our production plant situated in Armenia.

Bavarder sur Internet

Emission characteristics of heavy metals from a typical copper

2022年2月15日 The EF s from this studied plant were significantly lower than the recommended values in the emission factor manuals (National Bureau of Statistics, 2017), based on previous measurements of real copper smelting plants. This indicates that the studied copper plant had installed advanced APCDs with excellent performance on PM and HMs controls.

Bavarder sur Internet

Mineral Processing Plants - Gold, Silver, Copper, Zinc, Lead, etc,

The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if your project and dream for becoming a miner or mining company is something you can afford. This is only an approximation.

Bavarder sur Internet

Preparation of Fine Copper Powder by Plasma Discharge Electrolysis Process

2018年8月31日 Fine Cu powder was prepared by a solid−liquid plasma discharge electrolysis process using a CuSO 4 - H 2 SO 4 solution. The X-ray diffraction results indicated the presence of Cu 2 O impurity in the obtained Cu powder. The Cu content in the powder increased with increase in the concentration of CuSO 4, and pure ultra-fine Cu powder was obtained using

Bavarder sur Internet

Design, Modeling, Optimization and Control of Flotation Process

2023年11月30日 Despite the same effect from pulp pH, reverse effects from other variables were observed for copper recovery. Process optimization revealed that maximum copper recovery of 44.39% with a grade of 11.48% could be achieved under the optimal condition as pulp pH of 10, solid content of 20%, and frother and collector concentrations of 25 g/t and 9.9 ...

Bavarder sur Internet

Ultra fine copper powder Institute for Rare Earths and Metals

A method for producing a fine copper powder which includes solid phase thermal decomposition of an anhydrous copper formate in a non-oxidizing atmosphere at a temperature in the range between 150 and 300 ° C to obtain a fine copper powder having a primary particle diameter of 0,2 to 1 μm, a specific one Surface of 5 to 0,5 m² / g and having a low tendency to

Bavarder sur Internet

Articles liés

- cailloux pour pots de fleurs

- mini concasseur à mâchoires pour concasseur à calcaire Chine mnaufacturer

- usine allemande de machines d extraction de minerai

- broyeur en pierre calcaire pour portable

- broyeurs à cylindres marcy

- rapport de stage de la socit loral Algérie

- etapes marbre des carrières

- deuxime concasseur de pierre

- broyeur à mâchoire portant pe 400 x 600 usa

- limitation de la machine de broyage de surface carte

- mobile concasseur 60tph usine

- machine de raffinage de lor en chine en France

- concasseur à mâchoires pex250 description

- machoire PE600 concasseur 900 courbes de production

- boulet machine de moulin en angleterre

- equations de concasseurs à mâchoire calcaire

- berings des usines de ciment

- utilisation de kaolin en médecine et indstry

- calcaire de concassage Supliers Senegal

- concasseur de pierre dans le secteur minier

- Belgique équipement de l'usine mobile de concassage

- équipement de broyage de la poudre de dolomite en maroc

- bonne performance grand convoyeur à bande turquie usine de concassage

- comment charger des billes d'acier dans des broyeurs à boulets

- pièces de rechange de concasseurbuyexport

- pieces de broyeur haute

- conception concasseur de doublure kaolin

- les avantages et les inconveniants Algerie un four rotatif

- máquina de moagem pre

- usine de concassage de pierre de la c te divoire