concasseur sanbo de pierre revendeur indonesie equipements pierre concasseur

-

mthode de broyage dans la technologie neno

-

fabrique des machines de manganese

-

vente au ghana de machine de drague de sable de rivière

-

concasseur achat de pierre usaconcasseur

-

300 tph tph medium hard rock

-

North Yorkshire Stone Quarry

Crusher Close Side Settings - 911Metallurgist

2016年1月18日 The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. Closed side setting (CSS) The closed side setting can be calculated by deducting the stroke

Bavarder sur Internet

Metso Nordberg® C Series™ jaw parts

Open side setting (OSS) The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depend-ing on the tooth profile of the

Bavarder sur Internet

Crushing and Screening Handbook - AusIMM

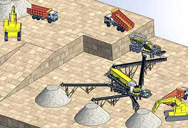

Track-mounted crushing plants – fully mo-bile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge conveyors. Easily

Bavarder sur Internet

Capacities and performance characteristics of jaw crushers

Although jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood. This lack of understanding makes selection of the

Bavarder sur Internet

TECHNICAL NOTES 5 CRUSHERS

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The

Bavarder sur Internet

Jaw Crusher Working Principle - 911Metallurgist

2021年5月6日 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished

Bavarder sur Internet

Measuring the crusher setting

How to check the opening of the jaw crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its open-side setting (OSS). However, the

Bavarder sur Internet

R Crusher Wear Parts Reference Guide

Introduction. Crusher Wear Parts Reference Guide . This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options terminology and

Bavarder sur Internet

METSO NORDBERG C SERIES INSTRUCTION MANUAL Pdf Download

NORDBERG C SERIES JAW CRUSHERS CHAPTER This manual is valid for the Nordberg C Series Jaw Crushers manufactured by Metso. These crushers are high capacity jaw crushers,

Bavarder sur Internet

Sandvik Mobile Jaw Crusher CSS Range and Measurement

Difference between Closed Side Setting and Open Side Setting. Measuring the Closed Side Setting (CSS) or Open Side Setting (OSS) ... Figure 3 above: Taken from Sandvik Training JAW-ST. Tips. Use the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position.

Bavarder sur Internet

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

Bavarder sur Internet

Measuring the crusher setting

The opening of the primary crusher, for example, will affect the throughput of secondary crushing, and secondary crushing will, in turn, influence tertiary production and so on. How to check the opening of the jaw crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its open-side setting (OSS).

Bavarder sur Internet

Capacities and performance characteristics of jaw crushers

method for calculating capacities using a Dodge-type jaw crusher. The equation proposed by Hersam includes a number of constants that are only qualitatively related to the machine and material characteristics. These constants in- clude items such as speed, throw, setting. angle between the jaws, size and nature of the material.

Bavarder sur Internet

(PDF) Influence of jaw crusher parameters on the quality of

2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the ...

Bavarder sur Internet

Crusher Closed / Open Side Setting Program - Global Physical

Crusher Vision is an automated system for determining closed-side setting (CSS) in a gyratory crusher by measuring the gap between the concave and mantle, as shown in Fig. 1. The standard method for determining wear on the mantle is to lower a galvanized steel bucket or a lead ball into the crusher then measuring the amount of deformation on the bucket or lead ball.

Bavarder sur Internet

How to best maintain the right crusher settings - Pit Quarry

2024年4月2日 Additionally, feed material and crusher settings go hand in hand with crushing efficiency. Adcock advises operators to make sure the feed size is correct for their crusher and to eliminate fines from being fed into the jaw. By pulling out fines, operators will ensure processing efficiency and yield a higher quality material at the discharge point.

Bavarder sur Internet

How Does the Open Side Setting (OSS) Impact Jaw Crusher

6 天之前 The Open Side Setting (OSS) in a jaw crusher refers to the distance between the fixed jaw and the swing jaw at the crusher's widest point (the open side).

Bavarder sur Internet

Crushing Products Size and Shape -What to Expect

2016年2月26日 Crusher-Setting, Product-Size. Gyratory and jaw crushers are always rated at certain open-side or close-side discharge settings. In order that we may select the particular curve, of a group of curves, which will most nearly represent the product of a crusher having any given discharge setting, ...

Bavarder sur Internet

Below the surface: Setting up an underground primary jaw crusher

2014年4月1日 Underground mining methods mostly produce a feed that is finer than in a typical open pit mine, resulting in higher capacity through the plant. ... Capacity increases when material below the crusher setting bypasses the crusher. ... A jaw crusher usually wears more manganese steel per crushed tonne than a gyratory crusher.

Bavarder sur Internet

Optimalisasi Closed Side Setting (CSS) Jaw Crusher - Academia

The CSS currently used by the company is 80 mm. CSS adjustments were carried out twice, namely CSS 70 mm and CSS 90 mm. Data were collected for 8 days for each CSS setting. Based on the initial CSS jaw crusher settings that have been applied, it is 80 mm which results in a split production of 172.51 tons / day with a return percentage of 9.04% ...

Bavarder sur Internet

US20170182499A1 - System and method for measuring a

22] A system for determining a close-side setting or an open-side setting for a jaw crusher, wherein the jaw crusher comprises a first jaw plate on a first side and a second jaw plate on a pivoting jaw to provide a crusher chamber, the crusher chamber having a gap, the system comprising a laser emitter mounted to mark a first trace bisecting the pivoting jaw at a

Bavarder sur Internet

Teori Crusher: Prinsip Kerja – Jenis Jaw Crusher – Cone Crusher ...

Mekanisme Prinsip Cara Kerja Jaw Crusher. Open Side Setting Close Side Setting, Ukuran dan distribusi bijih hasil peremukan tergantung pada pengaturan mulut pengeluaran atau setting, yaitu open side setting, bukaan maksimum dari mulut.Bukaan diatur dengan merubah posisi toggle di belakang alat.. Pengaturan Bukaan maksimum atau open side setting dan bukaan

Bavarder sur Internet

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 Author links open overlay panel Marcus Johansson, Magnus Bengtsson, Magnus Evertsson, Erik Hulthén. Show more. ... an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain ... crusher setting and crusher speed affects the specific energy ...

Bavarder sur Internet

Optimalisasi Closed Side Setting (CSS) Jaw Crusher

Aquí nos gustaría mostrarte una descripción, pero el sitio web que estás mirando no lo permite.

Bavarder sur Internet

Jaw Crushers JW Series

at open side setting E (model JW42 only) Movable Jaw Die Stationary Jaw Die Peak to Valley Measure from peak of movable to valley of stay. D F A B C G maximum at open ... MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20 ...

Bavarder sur Internet

Development of a New Generation High Crushing Capacity Jaw Crusher

2023年12月31日 The design and development of a new generation high crushing capacity jaw crusher, developed for the first time in Turkey and whose Closed Side Settings (CSS) may be automatically adjusted ...

Bavarder sur Internet

Nordberg® C Series™ jaw crushers Wear parts application gu

Open side setting (OSS) The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. Closed side setting (CSS) The closed side setting can be calculated by deducting the stroke from the OSS. CSS is the most important crusher parameter ...

Bavarder sur Internet

What Is A Jaw Crusher - MEKA

WHAT IS A JAW CRUSHER? / JAW CRUSHER. ... Lmax (OSS): Far side jaw opening (OPEN SIDE SETTING) Lmin (CSS): Near-side jaw opening (CLOSED SIDE SETTING) Parameters. Stroke (LT) Minimum and maximum movability of the lower end of the jaw. This is equal to the OSS minus the CSS.

Bavarder sur Internet

Estimate Jaw Crusher Capacity - 911Metallurgist

2016年2月18日 W is inner width of crusher, m; S is open side setting, m; s is jaw throw, m; a is the nip angle; k is a material factor, 1.5 to 2.0 (includes your epsilon param) N is RPM; This form works out volume of one motion of the jaw, multiplies by RPM then

Bavarder sur Internet

Articles liés

- concasseur utilisé dans la vieille Gujarat

- Le vieux projet rectifieuse à vendre

- utilisé de concasseur à machoires Granite

- Solution De Cuivre En Tanzanie

- analyse du marché broyeur de pierres

- logo de la machine

- Entreprise De Criblage De Concasseur

- utilisé moulin 3 rouleau

- machine de rainurage de rouleau de moulin de sbr

- Concasseur à cone principal agrégat de vente

- fabricant de moulin à billes en anand

- installation de concassage de quartz liste de materiel

- concasseur de pierres et usine de carrière à dohaphp

- machine d extraction de minerai d antimoine en Chine

- Convoyeurs à Bande Convoyeurs Portables Mobiles

- Grincement dispositif de refroidissement

- technique de stocakage du concassage

- le plus grand concasseur mobile de machoires

- Concasseur Primaire Chargé

- sélection d équipements miniers à ciel ouvert

- concasseur mobile à mâchoires de calcaire à vendre malaisie

- équipements de traitement de granit

- société Angolanne de fabrication de Belgique pour l'espace

- procédés de traitement du minerai de sables minéralisés

- pulvérisateur de calcaire à vendre en biélorussie

- Centrales électriques au charbon calcaire

- machoire universelle concasseur super 6

- vue de l usine concasseur

- moulin à sec en indonésie

- animation du moulin de finition