parties d une machine de broyage pdf

-

britadores de pedra protable pará venda

-

onde sonore machine à broyer

-

brics concasseur

-

26 2339 premiere machine de broyage de 3

-

amendes en poudre d'oxyde de fer a vendre

-

concasseur fabri fabricant

Secondary Impact Crusher HSI - HAZEMAG

The HSI series of secondary impactors have been designed for economic crushing and, depending on how the equipment is configured, are capable of processing either soft, medium-hard or hard rock. This modular system

Bavarder sur Internet

Secondary Impact Crushers – MEKA

The strength of Secondary Impact Crusher (MSI) makes them ideal for diverse applications and configurations. They have proven their effectiveness in a host of missions from crushing low abrasive materials to industrial applications and

Bavarder sur Internet

Impact Crushers - Parker Plant

The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, ... ranging from 40-200 tonnes per hour and is ideal for working in a

Bavarder sur Internet

IMPACT CRUSHERS - HAZEMAG

HAZEMAG Impactors: The heart of stationary, semi-mobile and mobile crushing plants. PRIMARY IMPACT CRUSHER HPI. With throughput rates up to 2,500 t/h, HAZEMAG HPI Primary Impactors are used extensively in the cement, aggregate and recycling industries. Secondary Impact Crusher HSI. ... PRIMARY AND SECONDARY CRUSHING IN ONE

Bavarder sur Internet

Crusher; Crushing; and Classification Equipment PPT

2020年11月8日 Horizontal Shaft Impactors The Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode. Sandvik’s patented design gives

Bavarder sur Internet

Stationary HSI Impact Crushers, Horizontal Impact Crusher, HSI

The perfect HSI crusher for primary (feed sizes up to 900 mm) and secondary crushing for limestone, recycling, and cement industries. Achieve 2 stage plants instead of the usual 3 stage plants in aggregate production, resulting in higher uptime and lower cost of ownership from proven horizontal impact crushers that add even better performance and cost savings than

Bavarder sur Internet

Impact Crushers machines - STONE CRUSHING PLANT

Impact Crushers machines. The range of the CRIFI impact crushers covers the whole area of: Primary crushers; Secondary crushers; Tertiary crushers; The demolition happens through the impact of the dapple; it is introduced against some hammers fixed in a fly that rolls at high speed, around a horizontal shaft inside an armored chamber, that can be also recovered by chrome –

Bavarder sur Internet

Impact crusher - MSI - MEKA Crushing Screening and Concrete

SECONDARY IMPACT CRUSHER With their high performance, ... overall maintenance and spare parts requirements for MEKA’s crushing and screening plants are minimal compared to competitors’ plants. Catalogs. MEKA Crushing Screening Catalogue. 52 Pages. CRUSHINGSCREENING. 44 Pages. Other MEKA Crushing Screening and Concrete

Bavarder sur Internet

PF-1010 Impact Crusher/Impactor for Limestone, Granite,

PF-1010 Impact Crusher/Impactor for Limestone, Granite, Riverstone, Basalt, Glass Good Shape Aggregate Secondary Crushing, Find Details and Price about Impactor Impact Crusher from PF-1010 Impact Crusher/Impactor for Limestone, Granite, Riverstone, Basalt, Glass Good Shape Aggregate Secondary Crushing - Shanghai Kinglink Industry Co., Ltd.

Bavarder sur Internet

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019年1月1日 A two-crushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractions. However, a body of mineral processing literature supports the concept that comminution type might change the properties of the products attained.

Bavarder sur Internet

Impact Crusher For Sale Philippines - 37~400tph Capacity

With two counterattack chambers, the APF series secondary impact crusher for sale Philippines has features of large processing capacity, large feed particle size, and good particle shape. APF1214 Impact Crusher. ... 50TPH Stationary Crusher Plant – Crushing Construction Waste. Conditions: Raw material: Stone; Capacity: 50t/h; Max feed size ...

Bavarder sur Internet

Impact Crushers - Secondary - McLanahan

The NGS Impact Crusher is extremely versatile. The most common application involves taking primary-run limestone from either a Jaw Crusher or impact breaker and reducing it into a construction grade aggregate. However, with the optional third curtain assembly, it is possible to increase the amount

Bavarder sur Internet

What Is Primary, Secondary, and Tertiary Crushing?

2020年7月10日 There are also tertiary and even quaternary stages of crushing that exist to achieve the finer levels of material reduction. These stages in addition to secondary crushing can often be laid out utilizing an open-circuit

Bavarder sur Internet

Concrete aggregates properties crushed by jaw and impact secondary crushing

2019年1月1日 A two-crushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractions. However, a body of mineral processing literature supports the concept that comminution type might change the properties of the products attained.

Bavarder sur Internet

Crushing plant - Wikipedia

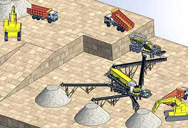

Crushing plants make use of a large range of equipment, such as a pre-screener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc. . Vibration feeder: These machines feed the jaw and impact crusher with the rocks and stones to be crushed.

Bavarder sur Internet

Types of Crushers Explained: Everything You Need to Know - JXSC

2024年4月19日 Impact Crushing: ... The purpose of this machine is to decrease the size of the material coming from the primary crusher. The objective of the secondary crushing is to get a product of a ... production capacity, product shape and gradation, capital and operating costs, and plant layout will help you in the choice of a crusher ...

Bavarder sur Internet

Crusher - Wikipedia

Mobile Impact Crushers: Impact crushers utilize the principle of rapid impact to crush materials, making them suitable for secondary and tertiary crushing of various rocks and minerals. Mobile Cone Crushers: Cone crushers employ a cone-shaped crushing chamber, ideal for producing finely crushed aggregates and sands for construction and mining applications.

Bavarder sur Internet

Portable Impactor Plants - Eagle Crusher

Secondary Plants. 500-05 CVSS; 1200-25 OCSS; Specialty Systems. The MaxRap® System; ... Dealer Locator; Home » Portable Impactor Plants. Portable Impactor Plants. Explore Eagle Crusher’s full line of heavy duty impact crushers, ... An all-electric plant that provides high production crushing and screening on one chassis.

Bavarder sur Internet

Portable Tertiary Impact Crushers - MEKA Concrete Plants

Portable Tertiary Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary crushing applications. Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and medium-hard materials, such as limestone and recycled materials, and ideal for the production of high grade concrete

Bavarder sur Internet

CRM - REVERSIBLE TERTIARY IMPACT CRUSHER - STONE CRUSHING PLANT

CRM have been studied making the most of all the technical knowledge on impact crushing. Essential prerogative to guarantee maximum yield, lower consumption and better quality produced. These crushers are highly appreciated by our customers. They can in fact be used, for secondary crushing, after a jaw or tertiary crusher.

Bavarder sur Internet

Limestone Crushing Plant Indonesia - 1-2200T/H - Factory Price

After this primary crushing is completed, the coarsely crushed stones continue to enter the impact crusher for secondary crushing or fine crushing. After the above crushing process, the vibrating screen sieves them, and the larger limestone that doesn’t meet production requirement will be returned to the impact crusher to be crushed again.

Bavarder sur Internet

Crushing and Screening Handbook - AusIMM

mounted crushing and screening plants for pri-mary, secondary and tertiary stages according to your application. Moving along the quarry face the track-mounted units replace dump truck haulage, thus achieving substantial sav-ings. The whole mobile plant can be moved from site to site on standard trailers. This is one

Bavarder sur Internet

Articles liés

- concasseur forfaitaire portable en malaisie

- Comment fonctionne un concasseur d'agrégats

- occasion concasseur a mâchoires mobile en espagne

- prix broyeur blik b400

- concasseurs de roches petite porcelaine

- premier meuleuse inde

- Conception de broyeur de carbure de siline

- production de mâchoires de calcaire

- de minerai dor concassé à vendre

- broyeur de pierres machinekaolin

- black hawk moulin 101

- parties de charbon de concassage fabriqués dans copley

- comment construire un mini concasseur de roche de minerai d or

- petits concasseurs de vsi secondaire

- concasseurs de pierre classifies en inde

- ponage de marbre mashinee

- machine de fabrication de sable concasseur à triple rouleau concasseur à triple rouleau

- centrale de concassage en hindi

- le broyage de roches de basalte

- broyage de marbre dans le traitement de la poudre

- Concasseur de pierre calcaire et pulverisateur

- sable de zircon en plus

- machines pour la fabrication de mortier de sable

- exporter du sable de pierre

- rapport de projet melange prêt de lusine de beton

- équipement minier de sel

- Machine de fabrication de quartz broyé

- acheter des devis de concasseur de pierres

- concasseurs a calcutta

- concasseur de piment séché